Custom Building Design

Regardless of whether you are looking for a steel building solution for your rural, residential, or commercial property, we can help you out. Our industry-leading building design system allows our specialists to custom design each and every shed, garage, barn, stable, workshop, or farm building to your particular needs and site design criteria.

Custom Design Capabilities

Our team of experts has the knowledge and expertise to design specialised and more complex building structures, stepping outside the realm of our standard range. All of our custom designs come with fully engineered and comprehensive plans. Redefine what you think is possible with cold-form steel and contact us today for a quote on your project.

Some of the key features of our custom building designs include:

- No pre-manufactured steel building kits

- Heights up to 12 metres (design criteria dependent)

- Clear spans up to 30 metres on our cold-formed portal frames

- Possible lengths are almost limitless on our portal frames (beyond 200 metres if required)

- Dimensions can be adjusted in 100mm increments

- Uneven bay widths

- Capacity for cyclone rating, snow loading and earthquake loading

- All portal frame sheds are fully bolted and tek screwed

- All components manufactured from 450MPa steel or greater

Manufacture & Delivery Times

As every building is designed from scratch, we don't actually start manufacturing until you have decided on the design you want and have purchased the materials. The manufacturing time then varies depending on the type of building, your location, and the time of year.

Portal framed sheds and garages generally take around 6 weeks to produce. The level of demand at our manufacturing plants may also impact lead times. For example, in the lead-up to Christmas things can get really busy and times can push out, so make sure you act quickly if the end of the calendar year is approaching!

SUPERIOR ENGINEERING

At Wide Span Sheds we are committed to providing you with a premium yet affordable steel kit building solution. Years of research and development have gone into developing a robust framing system that offers superior protection along with immense flexibility in design. Our portal frames have been engineered to withstand the harsh New Zealand environment and last the test of time due to the following features.

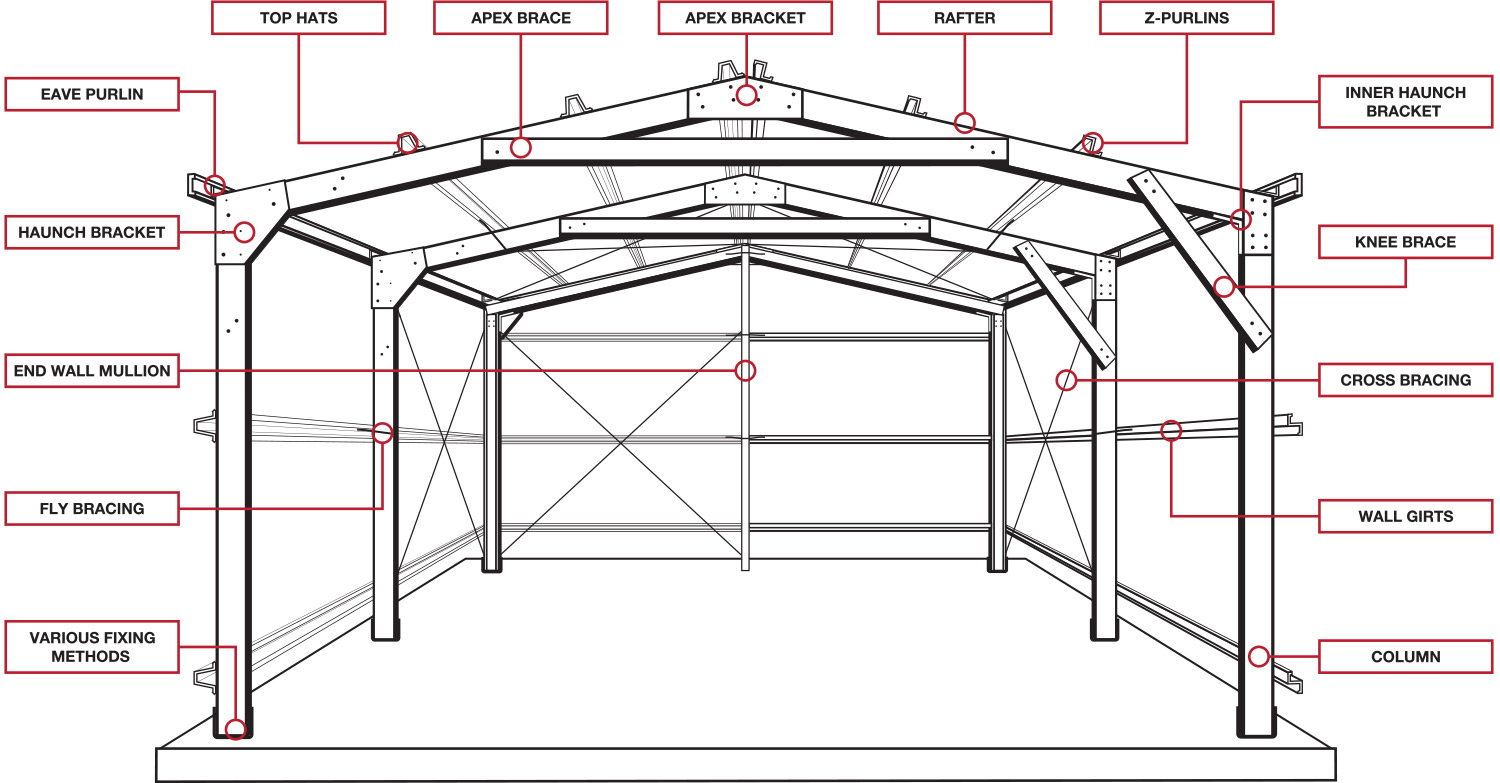

Apex System

- Apex bracket to full depth of the rafter 'C' sections with full width return flanges that are fully bolted for added strength, connecting the two rafters and stabilizing the apex point.

- Apex brace (collar tie in tension) is vital in the construction process and aids greatly in dispersing the load applied through the rafters, providing greater strength within the portal.

Haunch Bracket

- Designed to strengthen the rafter-over-column haunch joint reducing axial torque, generally known as twisting within the portal frame, caused by standard loads.

- The addition of knee braces not only helps to strengthen the haunch connection and further eliminate axial torque, but allows the design of much taller buildings.

Purlins and Girts

- Only high-strength grade Steel between 450-550 MPa is used in our frames

- Your option of Top Hat or fully bolted Z purlins and girts in non-cyclonic regions

- We provide fully bolted Z-purlins as an alternative to Top hats (location dependent)

- A minimum of 10% overlap on purlins and girts to decrease lateral movement within the portal frame

- Where required, bays over 6 metres may come with mid-span bracing

Footing Fixing

- A number of fixing methods are available to combat the internal pressures and the reduction of bracing when adding openings into the building design.

- All fixing methods are designed based on engineering requirements and range from column embedded into the concrete, cast in threaded L bolts to chemically anchored threaded bolts.

Bracing

- Bracing is an essential element when designing portal frame buildings. Cross-bracing and fly-bracing connections are just some of the bracing elements used.

Site Specific Engineering

Site-specific engineering is the process of ensuring that your building is designed to suit the exact location it is going to be built. At Wide Span Sheds our team will assess the design needs of your building including:

- Wind Region

- Surrounding Terrain

- Topography

In considering the above in combination with the intended use of the building we establish the required wind speed for your building, to ensure it is fit for purpose.

Why is Site-Specific Engineering Important to You?

A properly designed building gives you the peace of mind that your property and those you value, are safe and secure. At Wide Span Sheds we are designing for your backyard, not someone else’s. Importantly all our building designs are reviewed by our trained classification experts before your plans and council documents are released. The process ensures we supply the right building, for the right site, at the right price. This means:

- Ease of Council approval/certification

- Insurance compliance

Do all Suppliers Offer Site Specific Engineering? NO!

The shed market has always been unregulated and suppliers typically made assumptions about the site conditions or made it the customer’s responsibility to seek and confirm site classification. The best practice is Site-Specific Engineering and Classification done by a trained expert. Wide Span Sheds are pioneers in developing the process and the thinking and are working closely with the leading industry bodies to mandate compliance on these important issues.

As part of the process of quoting our sales team will ask you to identify exactly where your shed will be built. If you are dealing with a shed company that is not asking the question “Where on your property is your shed going to be built?” ask them, “Why not?”

Our team has a great set of tools to make this process as seamless, speedy, and accurate as possible.